service and support and repair services

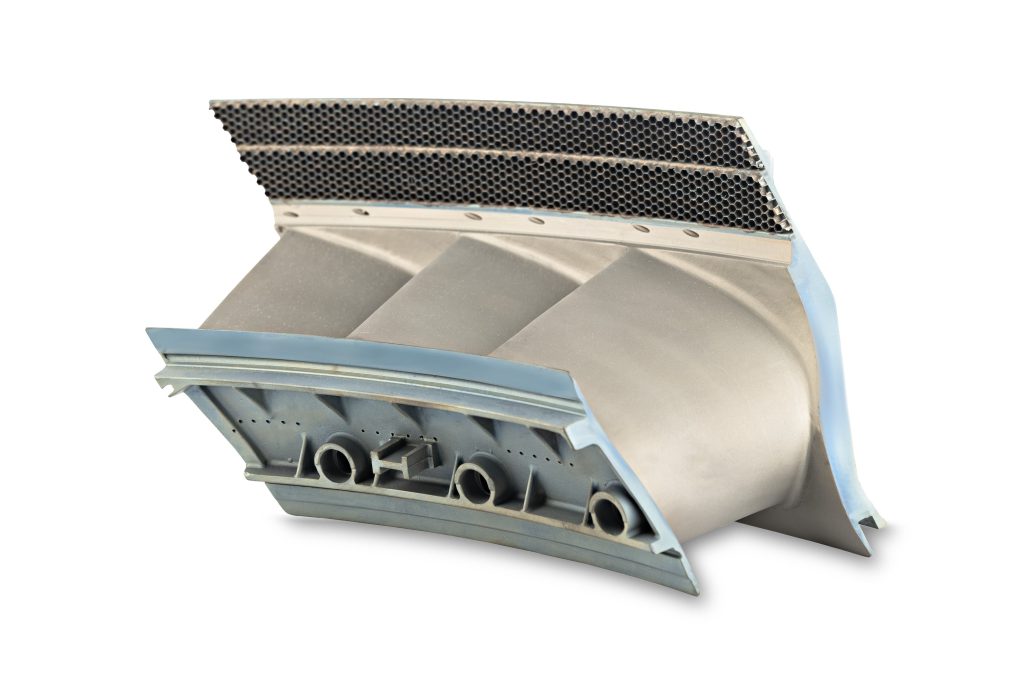

Turbine overhaul: Repairs of turbines are classified into level A, B, C, D, E repairs based on the hours of operation of these equipments, and in each of these stages, inspection-replacement and repairs are carried out on the equipment based on the manufacturer's instructions. ⦁ Daily, weekly, monthly, 6-month and one-year preventive maintenance ⦁ Small case repairs ⦁ Major repairs of turbo compressors and turbo generators and station facilities ⦁ Unforeseen repairs in gas pressure boosting stations and power plants Repairs of turbines are classified into level A, B, C, D, E repairs based on the hours of operation of these equipments, and in each of these stages, inspection, replacement or repairs are done on the equipment based on the manufacturer's instructions, for example : ⦁ In level A or 10,000-hour repairs, alignment of the turbine cases with respect to the shaft is checked during the broscope operation, and if necessary, necessary adjustments are made according to the internal protocol. ⦁ During level B repairs or 20,000-hour repairs, in addition to the operations performed in the previous paragraph, the GG part is separated from the PT and the hot part of the engine in the CT area is also dismantled. And the Vane1 assembly and combustion chamber are replaced and the engine is reassembled. ⦁ In level c repairs or 40,000 hours, in addition to the operation of paragraphs 1 and 2, Blade1 CT-Blade3 PT are also replaced and the cold parts of the engine are also inspected. In addition, NPT tests are also performed on the hot and cold parts of the engine. service and support and repair services